Product Description

Product Description

Our business:

1. Produce and customize various bearing brands. (we can customize your packaging according to your design and laser engrave your brand in the product. All copyright belongs to the customer. We promise not to disclose any information.)

2. Distribute the world famous bearing brands, such as: NSK, Timken, NTN, IKO, Nachi, CZPT HCH etc.

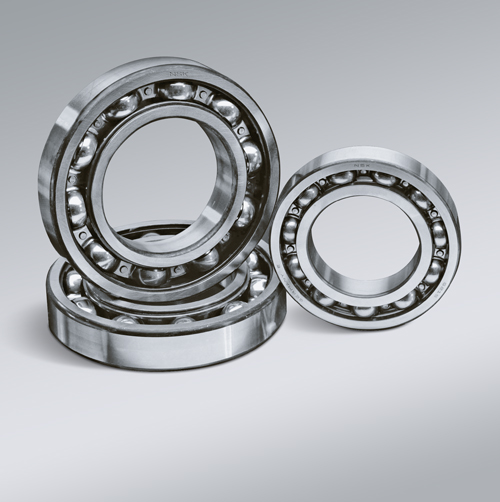

Our products include: deep groove ball bearings, tapered roller bearings, cylindrical roller bearings, self-aligning roller bearings, automobile bearings and thousands of other bearing models. We can also customized non-standard bearing according to customers requirements or drawings.

A wide range of applications:

• agriculture and forestry equipment

• automotive and industrial gearboxes

• automotive and truck electric components, such as alternators

• electric motors

• fluid machinery

• material handling

• power tools and household appliances

• textile machinery

• 2 Wheeler.

| Product Name | Ball bearing/roller bearing/insert bearing/Auto bearing/Linear bearing/Slide guide/needle bearing |

| Brand Name | BDL/NTN/NSK/KOYO/NACHI/TIMKEN/IKO/HCH |

| Material | Chrome Steel ,Stainless steel,Ceramic,Nylon |

| Precision Grade | P0,P6,P5,P4,P2(ABEC1, ABEC3, ABEC5, ABEC7, ABEC9) |

| Greese | SRL ,PS2, Alvania R12 ,etc |

| Certifications | ISO 9001 |

| Package | Box,Carton,Wooden Box,Plastic Tube or Per buyers requirement . |

| MOQ | 2PCS |

| Serice | OEM |

| Sample | Available |

| Payment Term | TT or L/C or Western Union |

| Port | HangZhou/HangZhou/ZheJiang |

Detailed Photos

Packaging & Shipping

Company Profile

Our Advantages

Our Advantages:

1. World-Class Bearing: We provide our customers with all types of indigenous bearing with world-class quality.

2. OEM or Non-Stand Bearings: Any requirement for Nonstandard bearings is Easily Fulfilled by us due to its vast knowledge and links in the industry.

3. Genuine products With Excellent Quality: The company has always proved the 100% quality products it provides with genuine intent.

4. After Sales Service and Technical Assistance: The company provides after-sales service and technical assistance as per the customer’s requirements and needs.

5. Quick Delivery: The company provides just-in-time delivery with its streamlined supply chain.

SAMPLES

1. Samples quantity: 1-10 PCS are available.

2. Free samples: It depends on the Model No., material and quantity. Some of the bearings samples need client to

pay samples charge and shipping cost.

3. It’s better to start your order with Trade Assurance to get full protection for your samples order.

CUSTOMIZED

The customized LOGO or drawing is acceptable for us.

MOQ

1. MOQ: 10 PCS standard bearings.

2. MOQ: 1000 PCS customized your brand bearings.

OEM POLICY

1. We can printing your brand (logo, artwork)on the shield or laser engraving your brand on the shield.

2. We can custom your packaging according to your design

3. All copyright own by clients and we promised don’t disclose any info.

FAQ

1.What is the minimum order quantity for this product?

Can be negotiated, we will try our best to meet customer needs.Our company is mainly based on wholesale sales,

most customers’orders are more than 1 ton.

2.What is your latest delivery time?

Most orders will be shipped within 7-15 days of payment being received.

3.Does your company have quality assurance?

Yes, for 1 years.

4.What is the competitiveness of your company’s products compared to other companies?

High precision, high speed, low noise.

5.What are the advantages of your company’s services compared to other companies?

Answer questions online 24 hours a day, reply in a timely manner, and provide various documents required by

customers for customs clearance or sales. 100% after-sales service.

6.Which payment method does your company support?

Do our best to meet customer needs, negotiable.

7.How to contact us quickly?

Please send us an inquiry or message and leave your other contact information, such as phone number,

account or account, we will contact you as soon as possible and provide the detailed information you need.

Please feel free to contact us, if you have any other question

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | Customized |

|---|---|

| Aligning: | Customized |

| Separated: | Customized |

| Rows Number: | Customized |

| Load Direction: | Radial Bearing |

| Material: | Bearing Steel |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can you provide examples of scenarios where high-speed rotation benefits from deep groove ball bearings?

High-speed rotation often benefits from the use of deep groove ball bearings due to their specific design features and capabilities. Here are examples of scenarios where deep groove ball bearings are advantageous for high-speed rotation:

- Electric Motors:

- Machine Tools:

- Spindles:

- Turbomachinery:

- Automotive Wheels:

- High-Speed Fans and Blowers:

- Rotating Machinery in Aerospace:

Deep groove ball bearings are commonly used in electric motors that require high-speed rotation, such as those found in industrial machinery, automotive applications, and household appliances. The low friction and smooth operation of deep groove ball bearings allow electric motors to achieve efficient and reliable performance at high rotational speeds.

In machine tools, such as milling machines and lathes, high-speed rotation is often necessary to achieve precise cutting and shaping operations. Deep groove ball bearings enable smooth and precise rotational motion, ensuring the accuracy and efficiency of machining processes at high speeds.

Spindles in various applications, including woodworking machines, CNC routers, and grinding machines, require high-speed rotation for precision operations. Deep groove ball bearings with their ability to handle both radial and axial loads and their low friction characteristics provide the necessary support and stability for high-speed spindle rotation.

In turbomachinery applications such as turbochargers, centrifugal compressors, and gas turbines, high-speed rotation is essential for efficient energy conversion and power generation. Deep groove ball bearings, with their ability to accommodate high speeds and handle radial loads, are used to support the rotating components of such turbomachinery, ensuring reliable and continuous operation.

Deep groove ball bearings are commonly used in automotive wheels, where high-speed rotation is required. They support the radial and axial loads encountered during vehicle operation and allow smooth rotation at highway speeds. Deep groove ball bearings contribute to the overall performance, safety, and durability of automotive wheels.

In applications such as industrial fans, HVAC systems, and turbo blowers, high-speed rotation is necessary to generate the desired airflow or pressure. Deep groove ball bearings are employed to support the fan or blower rotor, enabling smooth and efficient rotation at elevated speeds while minimizing energy losses.

In aerospace applications, various rotating components, including jet engines, helicopter rotors, and satellite mechanisms, require high-speed rotation. Deep groove ball bearings, designed to withstand high speeds and provide reliable performance, are used in these aerospace systems to ensure smooth operation and support critical functions.

In summary, deep groove ball bearings are beneficial for high-speed rotation in a wide range of scenarios. They find application in electric motors, machine tools, spindles, turbomachinery, automotive wheels, high-speed fans and blowers, as well as rotating machinery in the aerospace industry. The low friction, smooth operation, and ability to handle radial and axial loads make deep groove ball bearings suitable for supporting high-speed rotation while ensuring performance, precision, and reliability.

How does proper lubrication impact the performance and longevity of deep groove ball bearings?

Proper lubrication plays a crucial role in determining the performance and longevity of deep groove ball bearings. Here’s a detailed explanation of how proper lubrication impacts these aspects:

- Reduced Friction and Wear:

- Heat Dissipation:

- Corrosion and Contamination Protection:

- Noise and Vibration Reduction:

- Effective Load Distribution:

- Preservation of Bearing Integrity:

Lubrication creates a thin film of lubricant between the rolling elements and the raceway surfaces of the deep groove ball bearing. This film of lubricant reduces friction and minimizes metal-to-metal contact, resulting in lower wear and extending the bearing’s lifespan. Proper lubrication ensures that the lubricant film remains intact, preventing excessive friction, heat generation, and premature wear of the bearing components.

Deep groove ball bearings can generate heat during operation due to the sliding and rolling contact between the balls and the raceways. Adequate lubrication helps in dissipating this heat by carrying it away from the contact zone. Proper lubrication prevents the bearing from overheating, which can lead to accelerated wear, loss of dimensional stability, and even bearing failure.

Lubrication provides a protective barrier against corrosion and contamination. The lubricant helps to seal the bearing against external elements such as moisture, dust, dirt, and other contaminants that can degrade the bearing surfaces and compromise its performance. By preventing corrosion and contamination, proper lubrication extends the bearing’s service life and ensures reliable operation in challenging environments.

Insufficient or improper lubrication can result in increased noise and vibration levels in deep groove ball bearings. The lubricant acts as a cushioning medium, absorbing shocks and reducing the transmission of vibrations. Proper lubrication minimizes the generation of noise and vibrations, resulting in smoother and quieter operation of the bearing.

Proper lubrication ensures effective load distribution within the deep groove ball bearing. The lubricant film helps distribute the applied loads evenly across the rolling elements and raceways, minimizing stress concentrations and preventing premature fatigue or failure of the bearing. This promotes the bearing’s load-carrying capacity and enhances its overall performance and reliability.

Adequate lubrication helps preserve the overall integrity of deep groove ball bearings. It reduces the risk of surface damage, pitting, and scoring, which can lead to accelerated wear and premature failure. Proper lubrication also prevents the formation of rust and corrosion, preserving the structural integrity of the bearing components and ensuring their long-term functionality.

In summary, proper lubrication of deep groove ball bearings is essential for reducing friction and wear, dissipating heat, protecting against corrosion and contamination, minimizing noise and vibrations, facilitating effective load distribution, and preserving the overall integrity of the bearing. By ensuring proper lubrication, the performance and longevity of deep groove ball bearings can be significantly enhanced, resulting in reliable operation and extended service life.

What challenges are associated with minimizing noise and vibration in deep groove ball bearings?

Minimizing noise and vibration in deep groove ball bearings can be challenging due to several factors that can contribute to these unwanted effects. While deep groove ball bearings are designed to provide smooth and quiet operation, certain challenges need to be addressed to achieve optimal noise and vibration levels. Here’s a detailed explanation of the challenges associated with minimizing noise and vibration in deep groove ball bearings:

- Internal Clearance and Preload:

- Manufacturing and Assembly Variations:

- Lubrication:

- Operating Conditions:

- Application-Specific Challenges:

The internal clearance and preload of deep groove ball bearings can significantly impact noise and vibration levels. Insufficient preload or excessive internal clearance can result in excessive ball movement, leading to increased vibration and noise generation during operation. On the other hand, excessive preload can cause additional bearing stress and potential noise issues. Achieving the proper balance between preload and internal clearance is crucial to minimize noise and vibration in deep groove ball bearings.

Manufacturing and assembly variations can introduce irregularities or imperfections in deep groove ball bearings, leading to increased noise and vibration. Variations in ball size, shape, or surface finish, as well as irregularities in raceway profiles or cage design, can contribute to uneven loading, increased friction, and vibration. Strict quality control measures and precision manufacturing techniques are essential to minimize these variations and ensure consistent performance and reduced noise levels across deep groove ball bearings.

Lubrication plays a critical role in minimizing noise and vibration in deep groove ball bearings. Insufficient or improper lubrication can result in increased friction, wear, and noise generation. Inadequate lubrication film thickness can also lead to metal-to-metal contact and increased vibration levels. Proper selection and application of suitable lubricants, taking into account factors such as speed, temperature, and load conditions, are essential to maintain optimal lubrication and mitigate noise and vibration issues.

The operating conditions in which deep groove ball bearings are used can pose challenges in minimizing noise and vibration. Factors such as high speeds, heavy loads, misalignment, or temperature variations can induce vibrations and increase noise levels. In some cases, external factors such as electrical or magnetic fields can also impact the performance of deep groove ball bearings. Understanding the specific operating conditions and selecting bearings with appropriate load and speed ratings, as well as implementing proper alignment and environmental controls, are crucial to minimizing noise and vibration.

Each application may have its unique challenges in minimizing noise and vibration in deep groove ball bearings. For example, in electric motors, the electromagnetic forces can introduce additional vibrations and noise. In such cases, careful design considerations, such as optimizing bearing selection, mounting techniques, and implementing vibration dampening measures, may be necessary to address these application-specific challenges.

In summary, minimizing noise and vibration in deep groove ball bearings requires addressing challenges related to internal clearance and preload, manufacturing and assembly variations, lubrication, operating conditions, and application-specific factors. By understanding these challenges and implementing appropriate measures such as precise manufacturing techniques, proper lubrication practices, suitable bearing selection, and application-specific considerations, it is possible to achieve reduced noise and vibration levels, resulting in smoother and quieter operation of deep groove ball bearings.

editor by CX 2024-03-23