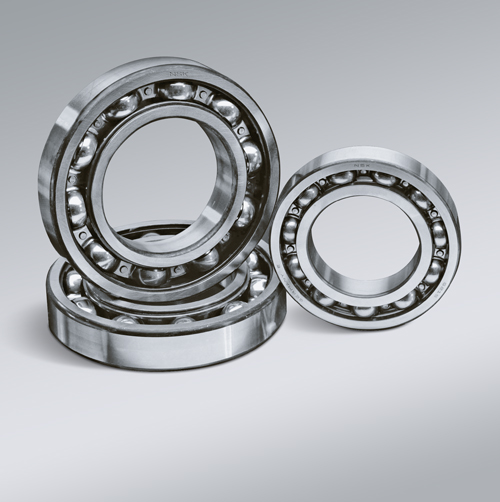

Product Description

China Factory 3d Printer Parts Deep Groove Ball Bearing 623zz 624zz 625zz 626zz 635zz 608zz 688zz

Single row deep groove ball bearings are particularly versatile. They are simple in design, non-separable, suitable for high and even very high speeds and are robust in operation, requiring little maintenance. Deep raceway grooves and the close conformity between the raceway grooves and the balls enable deep groove ball bearings to accommodate axial loads in both directions, in addition to radial loads, even at high speeds.

1. 623zz : 3mm*10mm*4mm

2. 624zz : 4mm*13mm*5mm

3. 625zz : 5mm*16mm*5mm

4. 626zz : 6mm*19mm*6mm

5. 608zz : 8mm*22mm*7mm

6. 688zz : 8mm*16mm*5mm

7. 635zz : 5mm*19mm*6mm

Detailed Photos

Product Parameters

Product Description

Any combination of closures is available

|

Basic |

Nominal Bearing Dimensions |

Preferred Shoulder Diameters |

||||||||||||

|

d |

D |

B,C |

r (min) |

da (min) |

da (max) |

Da (max) |

||||||||

|

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

|

|

604 |

4 |

0.1575 |

12 |

0.4724 |

4 |

0.1575 |

0.2 |

0.008 |

5.4 |

0.2126 |

6.6 |

0.2598 |

10.6 |

0.4173 |

|

605 |

5 |

0.1969 |

14 |

0.5512 |

5 |

0.2756 |

0.2 |

0.008 |

6.6 |

0.2600 |

7.4 |

0.2913 |

12.4 |

0.4880 |

|

606 |

6 |

0.2362 |

17 |

0.6693 |

6 |

0.2756 |

0.3 |

0.012 |

8.0 |

0.3150 |

8.6 |

0.3386 |

15.0 |

0.5910 |

|

607 |

7 |

0.2756 |

19 |

0.748 |

6 |

0.2756 |

0.3 |

0.012 |

9.0 |

0.3543 |

10.4 |

0.4094 |

17.0 |

0.6693 |

|

608 |

8 |

0.3149 |

22 |

0.8661 |

7 |

0.2756 |

0.3 |

0.012 |

10.0 |

0.3937 |

12.2 |

0.4803 |

10.0 |

0.7874 |

|

609 |

9 |

0.3543 |

24 |

0.9449 |

7 |

0.2756 |

0.3 |

0.012 |

11.0 |

0.4331 |

13.1 |

0.5157 |

12.0 |

0.8661 |

|

Basic |

Nominal Bearing Dimensions |

Preferred Shoulder Diameters |

||||||||||||

|

d |

D |

B,C |

r (min) |

da (min) |

da (max) |

Da (max) |

||||||||

|

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

|

|

624 |

4 |

0.1575 |

13 |

0.5118 |

5 |

0.1968 |

0.2 |

0.007 |

5.6 |

0.220 |

6.2 |

0.244 |

11.4 |

0.449 |

|

625 |

5 |

0.1969 |

13 |

0.6299 |

5 |

0.1968 |

0.3 |

0.012 |

7.0 |

0.276 |

7.6 |

0.299 |

14.0 |

0.551 |

|

626 |

6 |

0.2362 |

16 |

0.7480 |

6 |

0.2362 |

0.3 |

0.012 |

8.0 |

0.315 |

9.5 |

0.374 |

17.0 |

0.669 |

|

627 |

7 |

0.2756 |

22 |

0.8661 |

7 |

0.2756 |

0.3 |

0.012 |

9.0 |

0.354 |

12.2 |

0.480 |

20.0 |

0.787 |

|

628 |

5 |

0.3149 |

24 |

0.9448 |

8 |

0.3149 |

0.3 |

0.012 |

10.0 |

0.394 |

12.1 |

0.476 |

17.0 |

0.669 |

|

629 |

9 |

0.3543 |

26 |

1.5716 |

8 |

0.3149 |

0.3 |

0.012 |

11.5 |

0.453 |

… |

… |

14.0 |

0.945 |

|

Basic |

Nominal Bearing Dimensions |

Preferred Shoulder Diameters |

||||||||||||

|

d |

D |

B,C |

r (min) |

da (min) |

da (max) |

Da (max) |

||||||||

|

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

|

|

635 |

5 | 0.1969 | 19 | 0.7480 | 6 | 0.2362 | 0.3 | 0.012 | 7.0 | 0.276 | 9.5 | 0.374 | 17.0 | 0.669 |

|

636 |

6 | 0.2362 | 22 | 0.8661 | 7 | 0.8661 | 0.3 | 0.012 | … | … | … | … | … | … |

|

637 |

7 | 0.2756 | 26 | 1.5716 | 9 | 0.3543 | 0.3 | 0.012 | … | … | … | … | … | … |

|

638 |

8 | 0.3149 | 28 | 1.1571 | 9 | 0.3543 | 0.3 | 0.012 | 10.0 | 0.394 | … | … | 26.0 | 1.571 |

|

639 |

9 | 0.3543 | 30 | 1.1811 | 10 | 0.3937 | 0.6 | 0.571 | … | … | … | … | … | … |

|

Basic |

Nominal Bearing Dimensions |

Preferred Shoulder Diameters |

||||||||||||||

|

d |

D |

B |

r (min) |

da (min) |

da (max) |

Da (max) |

||||||||||

| Open | Shielded sealed | |||||||||||||||

|

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

|

|

685 |

5 | 0.1969 | 11 | 0.4331 | 3 | 0.1181 | 5 | 0.1969 | 0.15 | 0.006 | 6.2 | 0.244 | 6.2 | 0.244 | 9.9 | 0.390 |

|

686 |

6 | 0.2362 | 13 | 0.5118 | 3.5 | 0.1378 | 5 | 0.1969 | 0.15 | 0.006 | 7.4 | 0.291 | 7.4 | 0.291 | 11.7 | 0.461 |

|

687 |

7 | 0.2756 | 14 | 0.5512 | 3.5 | 0.1378 | 5 | 0.1969 | 0.15 | 0.006 | 8.5 | 0.335 | 8.5 | 0.335 | 12.7 | 0.500 |

|

688 |

8 | 0.3150 | 16 | 0.6299 | 4 | 0.1575 | 5 | 0.1969 | 0.20 | 0.008 | … | … | … | … | … | … |

|

689 |

9 | 0.3543 | 17 | 0.6693 | 4 | 0.1575 | 5 | 0.1969 | 0.20 | 0.008 | 10.7 | 0.421 | 10.7 | 0.421 | 15.2 | 0.598 |

|

Basic |

Nominal Bearing Dimensions |

Preferred Shoulder Diameters |

||||||||||||

|

d |

D |

B,C |

r (min) |

da (min) |

da (max) |

Da (max) |

||||||||

|

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

|

|

693 |

3 | 0.1181 | 8 | 0.3150 | 3 | 0.1181 | 0.15 | 0.006 | 4.3 | 0.169 | 4.3 | 0.169 | 7.3 | 0.287 |

|

W693 |

3 | 0.1181 | 8 | 0.3150 | 4 | 0.1575 | 0.15 | 0.006 | 4.2 | 0.165 | 4.2 | 0.165 | 6.8 | 0.268 |

|

694 |

4 | 0.1575 | 11 | 0.4331 | 4 | 0.1575 | 0.20 | 0.008 | 5.2 | 0.205 | 5.2 | 0.205 | 9.8 | 0.386 |

|

695 |

5 | 0.1969 | 13 | 0.5118 | 4 | 0.1575 | 0.20 | 0.008 | 6.6 | 0.260 | 6.6 | 0.260 | 11.4 | 0.449 |

|

696 |

6 | 0.2362 | 15 | 0.5906 | 5 | 0.1969 | 0.30 | 0.012 | 7.6 | 0.299 | 7.6 | 0.299 | 13.4 | 0.528 |

|

697 |

7 | 0.2756 | 17 | 0.6693 | 5 | 0.1969 | 0.30 | 0.012 | 9.0 | 0.354 | 9.0 | 0.354 | 15.0 | 0.591 |

|

698 |

8 | 0.3150 | 19 | 0.7480 | 6 | 0.2362 | 0.30 | 0.012 | 10.0 | 0.394 | 10.0 | 0.394 | 16.5 | 0.650 |

|

699 |

9 | 0.3543 | 20 | 0.7874 | 6 | 0.2362 | 0.30 | 0.012 | 11.0 | 0.433 | 11.6 | 0.457 | 18.0 | 0.709 |

|

Common Options |

|

|

Z |

: One Shield |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Aligning: | Non-Aligning Bearing |

|---|---|

| Separated: | Unseparated |

| Rows Number: | Single |

| Load Direction: | Radial Bearing |

| Material: | Bearing Steel |

| Transport Package: | Industrial Exporting Packing,or Upon The Customer′ |

| Customization: |

Available

| Customized Request |

|---|

How do deep groove ball bearings contribute to the smooth operation of electric motors?

Deep groove ball bearings play a crucial role in ensuring the smooth operation of electric motors. Their specific design features and capabilities contribute to the overall performance and efficiency of electric motors. Here’s a detailed explanation of how deep groove ball bearings contribute to the smooth operation of electric motors:

- Reduced Friction:

- Low Noise and Vibration:

- High-Speed Capability:

- Radial Load Support:

- Long Service Life:

- Versatility and Availability:

Deep groove ball bearings are designed to minimize friction between the rotating components of an electric motor. The smooth rolling motion of the steel balls within the deep raceway reduces frictional resistance, resulting in less energy loss and efficient power transmission. This leads to smoother operation and improved overall motor performance.

Deep groove ball bearings help dampen vibrations and reduce noise generation in electric motors. The precise alignment of the inner and outer rings, combined with the smooth rolling motion of the balls, minimizes vibrations that can cause noise. This results in quieter motor operation, which is particularly important in applications where noise reduction is desired, such as in household appliances or office equipment.

Electric motors often require high-speed rotation to achieve efficient performance. Deep groove ball bearings are designed to handle high rotational speeds, allowing electric motors to operate at their intended speeds without compromising performance or reliability. The smooth and continuous rolling motion of the balls within the deep raceway enables the motor to achieve and maintain high speeds with minimal friction and heat generation.

Deep groove ball bearings are capable of supporting both radial and axial loads. In electric motors, radial loads are common due to the weight and forces exerted on the rotating shaft. Deep groove ball bearings efficiently transmit and distribute these radial loads, providing support and stability to the motor’s rotating components. This ensures smooth and balanced operation, reducing the risk of premature wear or damage to the motor’s internal parts.

Deep groove ball bearings are designed for durability and long service life in electric motors. They are typically manufactured using high-quality materials and precision engineering techniques. This results in bearings that can withstand continuous operation, high-speed rotation, and various operating conditions without significant wear or performance degradation. The long service life of deep groove ball bearings contributes to the smooth and reliable operation of electric motors over extended periods.

Deep groove ball bearings are available in a wide range of sizes, configurations, and materials to suit different electric motor designs and applications. This versatility allows motor manufacturers to select the most appropriate bearing based on factors such as load requirements, speed capabilities, and operating conditions. The availability of deep groove ball bearings from numerous suppliers ensures easy sourcing and replacement options, further contributing to the smooth operation of electric motors.

In summary, deep groove ball bearings contribute to the smooth operation of electric motors through reduced friction, low noise and vibration levels, high-speed capability, effective support of radial loads, long service life, versatility, and availability. By incorporating deep groove ball bearings into electric motor designs, manufacturers can optimize performance, efficiency, and reliability, resulting in smooth and trouble-free motor operation in a wide range of applications.

How does proper lubrication impact the performance and longevity of deep groove ball bearings?

Proper lubrication plays a crucial role in determining the performance and longevity of deep groove ball bearings. Here’s a detailed explanation of how proper lubrication impacts these aspects:

- Reduced Friction and Wear:

- Heat Dissipation:

- Corrosion and Contamination Protection:

- Noise and Vibration Reduction:

- Effective Load Distribution:

- Preservation of Bearing Integrity:

Lubrication creates a thin film of lubricant between the rolling elements and the raceway surfaces of the deep groove ball bearing. This film of lubricant reduces friction and minimizes metal-to-metal contact, resulting in lower wear and extending the bearing’s lifespan. Proper lubrication ensures that the lubricant film remains intact, preventing excessive friction, heat generation, and premature wear of the bearing components.

Deep groove ball bearings can generate heat during operation due to the sliding and rolling contact between the balls and the raceways. Adequate lubrication helps in dissipating this heat by carrying it away from the contact zone. Proper lubrication prevents the bearing from overheating, which can lead to accelerated wear, loss of dimensional stability, and even bearing failure.

Lubrication provides a protective barrier against corrosion and contamination. The lubricant helps to seal the bearing against external elements such as moisture, dust, dirt, and other contaminants that can degrade the bearing surfaces and compromise its performance. By preventing corrosion and contamination, proper lubrication extends the bearing’s service life and ensures reliable operation in challenging environments.

Insufficient or improper lubrication can result in increased noise and vibration levels in deep groove ball bearings. The lubricant acts as a cushioning medium, absorbing shocks and reducing the transmission of vibrations. Proper lubrication minimizes the generation of noise and vibrations, resulting in smoother and quieter operation of the bearing.

Proper lubrication ensures effective load distribution within the deep groove ball bearing. The lubricant film helps distribute the applied loads evenly across the rolling elements and raceways, minimizing stress concentrations and preventing premature fatigue or failure of the bearing. This promotes the bearing’s load-carrying capacity and enhances its overall performance and reliability.

Adequate lubrication helps preserve the overall integrity of deep groove ball bearings. It reduces the risk of surface damage, pitting, and scoring, which can lead to accelerated wear and premature failure. Proper lubrication also prevents the formation of rust and corrosion, preserving the structural integrity of the bearing components and ensuring their long-term functionality.

In summary, proper lubrication of deep groove ball bearings is essential for reducing friction and wear, dissipating heat, protecting against corrosion and contamination, minimizing noise and vibrations, facilitating effective load distribution, and preserving the overall integrity of the bearing. By ensuring proper lubrication, the performance and longevity of deep groove ball bearings can be significantly enhanced, resulting in reliable operation and extended service life.

What challenges are associated with minimizing noise and vibration in deep groove ball bearings?

Minimizing noise and vibration in deep groove ball bearings can be challenging due to several factors that can contribute to these unwanted effects. While deep groove ball bearings are designed to provide smooth and quiet operation, certain challenges need to be addressed to achieve optimal noise and vibration levels. Here’s a detailed explanation of the challenges associated with minimizing noise and vibration in deep groove ball bearings:

- Internal Clearance and Preload:

- Manufacturing and Assembly Variations:

- Lubrication:

- Operating Conditions:

- Application-Specific Challenges:

The internal clearance and preload of deep groove ball bearings can significantly impact noise and vibration levels. Insufficient preload or excessive internal clearance can result in excessive ball movement, leading to increased vibration and noise generation during operation. On the other hand, excessive preload can cause additional bearing stress and potential noise issues. Achieving the proper balance between preload and internal clearance is crucial to minimize noise and vibration in deep groove ball bearings.

Manufacturing and assembly variations can introduce irregularities or imperfections in deep groove ball bearings, leading to increased noise and vibration. Variations in ball size, shape, or surface finish, as well as irregularities in raceway profiles or cage design, can contribute to uneven loading, increased friction, and vibration. Strict quality control measures and precision manufacturing techniques are essential to minimize these variations and ensure consistent performance and reduced noise levels across deep groove ball bearings.

Lubrication plays a critical role in minimizing noise and vibration in deep groove ball bearings. Insufficient or improper lubrication can result in increased friction, wear, and noise generation. Inadequate lubrication film thickness can also lead to metal-to-metal contact and increased vibration levels. Proper selection and application of suitable lubricants, taking into account factors such as speed, temperature, and load conditions, are essential to maintain optimal lubrication and mitigate noise and vibration issues.

The operating conditions in which deep groove ball bearings are used can pose challenges in minimizing noise and vibration. Factors such as high speeds, heavy loads, misalignment, or temperature variations can induce vibrations and increase noise levels. In some cases, external factors such as electrical or magnetic fields can also impact the performance of deep groove ball bearings. Understanding the specific operating conditions and selecting bearings with appropriate load and speed ratings, as well as implementing proper alignment and environmental controls, are crucial to minimizing noise and vibration.

Each application may have its unique challenges in minimizing noise and vibration in deep groove ball bearings. For example, in electric motors, the electromagnetic forces can introduce additional vibrations and noise. In such cases, careful design considerations, such as optimizing bearing selection, mounting techniques, and implementing vibration dampening measures, may be necessary to address these application-specific challenges.

In summary, minimizing noise and vibration in deep groove ball bearings requires addressing challenges related to internal clearance and preload, manufacturing and assembly variations, lubrication, operating conditions, and application-specific factors. By understanding these challenges and implementing appropriate measures such as precise manufacturing techniques, proper lubrication practices, suitable bearing selection, and application-specific considerations, it is possible to achieve reduced noise and vibration levels, resulting in smoother and quieter operation of deep groove ball bearings.

editor by CX 2024-04-25