Deep Groove Ball Bearings

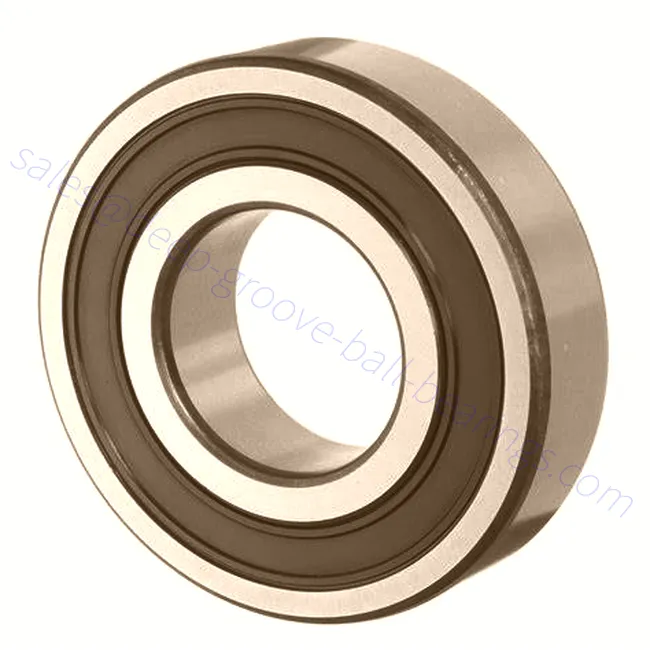

Sealed Deep Groove Ball Bearings

Deep groove ball bearings are one of the most common type of rolling bearings. The basic deep groove ball bearing consists of an outer ring, an inner ring, a set of steel balls and a set of cages.Deep groove ball bearing has a wide range of sizes and with simple structure, standardized machining process, reliability, durability and high-cost performance. Deep groove ball bearings can bear axial load in both radial and light axial directions and are easy to install at low maintenance costs.They have low friction torque and are optimized for low vibration and low noise, which are suitable for high-speed operation.

Applications: electric motors and generators, agriculture, material transportation, industrial gearboxes, food and beverage, industrial pumps, industrial fans, vehicles, etc.

As one of the leading deep groove ball bearings manufacturers, suppliers, and exporters of mechanical products, We offer deep groove ball bearings and many other products. Please get in touch with us for details.

Mail:[email protected]

Sealed deep groove ball bearings are similar to single-row bearings, except that they have steel or rubber shields installed on both sides of the bearing. These seals are pre-lubricated with grease to extend the lifespan of the bearing.

Many manufacturers use sealed ball bearings in contaminated environments that may otherwise influence the performance of the bearing. The shields help the bearing retain grease while preventing any contaminants from entering the bearing itself. More oversized deep groove ball bearings may even use machined brass cages for high-speed applications, where the cage prevents unwanted wear and tear.

Performance Benefits:

- More effective filtering minimizes bearing contamination, which extends service life.

- Lower power loss and higher efficiency across operating conditions

- Operates at higher speeds than standard sealed deep groove ball bearings

- Increased robustness prolongs bearing and fill service life

- Sealing friction is 50% less than that of a common solution

Applications Industries

- Automotive

- Chemical and Pharmaceutical

- Electric Motors

- Fans and Blowers

- Industrial Pumps and Compressors

- Petrochemical

- Power Transmission

- Cement