Product Description

Product Description

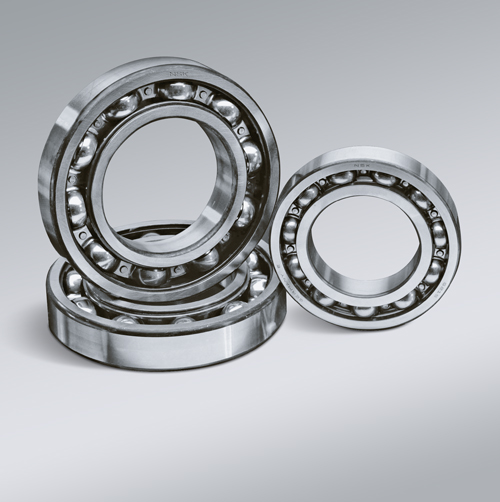

Bearing No. 61804 Thin-walled deep groove ball bearing-radial ball bearing

·Dimensions: 20x32x7mm

·Rubber seal on both sides

·100% Chrome Steel for higher resistance and durability

·Supports 18,000 rpm with grease, 24,000 rpm with oil

·Our high-quality bearing is made to reduce your replacement frequency and maintenance cost

Specifications for this item

Bearing Type: Thin-walled deep groove ball bearing

Brand: HXB or OEM brand

Material: chrome steel GCr15, AISL52100, SUJ2

Application: RV Reducer , auto parts, industrial robort, medical instruments

| Bearing Number | Boundary dimensions(mm) | Basic Load Rating | Limiting Speed(r/min) | Weight(kg) | ||||

| Bearig No | d | D | B | Cr | Cor | Grease | Oil | |

| 61800 | 10 | 19 | 5 | 1.8 | 0.93 | 28000 | 36000 | 0.005 |

| 61801 | 12 | 21 | 5 | 1.9 | 1 | 24000 | 32000 | 0.005 |

| 61802 | 15 | 24 | 5 | 2.1 | 1.3 | 22000 | 30000 | 0.005 |

| 61803 | 17 | 26 | 5 | 2.2 | 1.5 | 20000 | 28000 | 0.007 |

| 61804 | 20 | 32 | 7 | 3.5 | 2.2 | 18000 | 24000 | 0.015 |

| 61805 | 25 | 37 | 7 | 4.3 | 2.9 | 16000 | 20000 | 0.017 |

| 61806 | 30 | 42 | 7 | 4.7 | 3.6 | 13000 | 17000 | 0.019 |

| 61807 | 35 | 47 | 7 | 4.9 | 4 | 11000 | 15000 | 0.571 |

| 61808 | 40 | 52 | 7 | 5.1 | 4.4 | 10000 | 13000 | 0.026 |

| 61809 | 45 | 58 | 7 | 6.4 | 5.6 | 9000 | 12000 | 0.030 |

| 61810 | 50 | 65 | 7 | 6.6 | 6.1 | 8500 | 10000 | 0.043 |

| 61811 | 55 | 72 | 9 | 9.1 | 8.4 | 8000 | 9500 | 0.070 |

| 61812 | 60 | 78 | 10 | 9.1 | 8.7 | 7000 | 8500 | 0.093 |

| 61813 | 65 | 85 | 10 | 11.9 | 11.5 | 6700 | 8000 | 0.130 |

| 61814 | 70 | 90 | 10 | 12.1 | 11.9 | 6300 | 7500 | 0.138 |

| 61815 | 75 | 95 | 10 | 12.5 | 12.8 | 6000 | 7000 | 0.147 |

| 61816 | 80 | 100 | 10 | 12.7 | 13.3 | 5600 | 6700 | 0.155 |

| 61817 | 85 | 110 | 13 | 19.2 | 19.8 | 5000 | 6300 | 0.245 |

| 61818 | 90 | 115 | 13 | 19.5 | 20.5 | 4800 | 6000 | 0.258 |

| 61819 | 95 | 120 | 13 | 19.8 | 21.3 | 4500 | 5600 | 0.27 |

| 61820 | 100 | 125 | 13 | 20.1 | 22.0 | 4300 | 5300 | 0.28 |

| 61821 | 105 | 130 | 13 | 20.3 | 22.7 | 4000 | 5000 | 0.3 |

| 61822 | 110 | 140 | 16 | 28.1 | 30.7 | 3800 | 5000 | 0.5 |

| 61824 | 120 | 150 | 16 | 28.9 | 32.9 | 3400 | 4300 | 0.54 |

Application

Company Profile

Established in 1995, as a leading ball bearing manufacturer in China, HXB offers more than 1,000 kinds of ball bearing to fulfill our customers’ needs. With excellent production team and technical team, we can supply high quality products consistently.

After more than 20 years of development, HXB’s main products involves deep groove ball bearings, angular contact ball bearings, high precision spindle bearings, etc. Our bearings are wildly used in electric motors, machinery tool spindle, CNC, NEVs and other fields.

Certificates

Package

Exibition

FQA

1. Are you trading company or manufacturer?

We are factory more than 28 years.

2. What application do your products involved in?

Our products application fields mainly include motor, water pumps, household appliances, automobiles, motorcycles, power tools, engraving machines,reducers, machine tools, CNC machine centers, textile machinery, woodworking machinery, ets.

3. Can you make OEM products?

Yes, we can do OEM according to clients needs, develop and produce products according to drawings or sample provided by clients. We also have our brand HXB or YJB.

4. Does your company have quality assurance?

Yes, for 1 year.

5. What’s the competitiveness of your company’s products compared to the companies?

High precision, high speed, low noise.

6. How does the goods ship to customer?

By sea, by train, by air or express.

7.What is the production capacity of your company?

We have 48 productions lines. Annual output has reached 33,000,000pcs.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Precision Class: | P0,P5,P6, P4 |

|---|---|

| Grease: | Shell |

| Rows Number: | Single |

| Load Direction: | Radial Bearing |

| Material: | Bearing Steel |

| Transport Package: | Color Box+Carton |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the signs of wear or damage in deep groove ball bearings, and when should they be replaced?

Deep groove ball bearings, like any mechanical component, can experience wear or damage over time. It is important to identify the signs of wear or damage in bearings and know when they should be replaced to prevent further issues. Here’s a detailed explanation of the signs of wear or damage in deep groove ball bearings and when they should be replaced:

- Abnormal Noise:

- Excessive Vibration:

- Increased Temperature:

- Irregular or Uneven Operation:

- Visible Wear or Damage:

- Lubrication Issues:

- Operating Conditions:

Unusual noises, such as grinding, clicking, or rumbling sounds, can indicate bearing wear or damage. These noises may occur during operation and can be an indication of insufficient lubrication, misalignment, or the presence of foreign particles. If abnormal noise is detected, it is recommended to inspect the bearings promptly and replace them if necessary.

Excessive vibration during operation can be a sign of bearing wear or damage. Vibrations may occur due to misalignment, imbalance, or the presence of faulty bearings. If the vibration levels are unusually high and cannot be attributed to other factors, the bearings should be inspected and replaced if needed.

Significantly increased operating temperature of the bearings can indicate wear or damage. Excessive friction caused by worn-out or misaligned bearings can generate excessive heat. If the temperature of the bearings exceeds the recommended operating limits, it is advisable to investigate the cause and replace the bearings as necessary.

Irregular or uneven operation of the equipment or machinery can be a symptom of bearing wear or damage. This may manifest as erratic or jerky movements, decreased performance, or decreased efficiency. If such irregularities are observed, the bearings should be inspected to determine if replacement is required.

Physical inspection of the bearings can reveal visible signs of wear or damage. These signs may include pitting, rust formation, scoring, or discoloration on the bearing surfaces. Excessive wear or damage that affects the smooth rolling motion or integrity of the bearings should prompt immediate replacement.

Problems with lubrication, such as inadequate or contaminated lubricant, can contribute to bearing wear or damage. Insufficient lubrication can lead to increased friction, heat generation, and accelerated wear. If lubrication-related issues persist despite proper maintenance, it may be necessary to replace the bearings.

The operating conditions of the equipment or machinery can also influence the lifespan of deep groove ball bearings. Factors such as heavy loads, high speeds, extreme temperatures, exposure to corrosive environments, or prolonged use can accelerate wear or damage. In such demanding conditions, bearings may need to be replaced more frequently to ensure reliable operation.

It is important to note that the timing of bearing replacement depends on various factors, including the severity of wear or damage, the criticality of the application, and the manufacturer’s recommendations. Regular inspection and maintenance practices, as well as monitoring of the aforementioned signs, can help determine the appropriate timing for bearing replacement. Consulting with bearing manufacturers or maintenance professionals can provide valuable guidance in assessing the condition of deep groove ball bearings and making informed decisions regarding replacement.

In summary, signs of wear or damage in deep groove ball bearings include abnormal noise, excessive vibration, increased temperature, irregular or uneven operation, visible wear or damage, lubrication issues, and demanding operating conditions. Prompt replacement of bearings exhibiting these signs is essential to prevent further damage, avoid equipment failure, and ensure the continued smooth and reliable operation of machinery or equipment.

How does proper lubrication impact the performance and longevity of deep groove ball bearings?

Proper lubrication plays a crucial role in determining the performance and longevity of deep groove ball bearings. Here’s a detailed explanation of how proper lubrication impacts these aspects:

- Reduced Friction and Wear:

- Heat Dissipation:

- Corrosion and Contamination Protection:

- Noise and Vibration Reduction:

- Effective Load Distribution:

- Preservation of Bearing Integrity:

Lubrication creates a thin film of lubricant between the rolling elements and the raceway surfaces of the deep groove ball bearing. This film of lubricant reduces friction and minimizes metal-to-metal contact, resulting in lower wear and extending the bearing’s lifespan. Proper lubrication ensures that the lubricant film remains intact, preventing excessive friction, heat generation, and premature wear of the bearing components.

Deep groove ball bearings can generate heat during operation due to the sliding and rolling contact between the balls and the raceways. Adequate lubrication helps in dissipating this heat by carrying it away from the contact zone. Proper lubrication prevents the bearing from overheating, which can lead to accelerated wear, loss of dimensional stability, and even bearing failure.

Lubrication provides a protective barrier against corrosion and contamination. The lubricant helps to seal the bearing against external elements such as moisture, dust, dirt, and other contaminants that can degrade the bearing surfaces and compromise its performance. By preventing corrosion and contamination, proper lubrication extends the bearing’s service life and ensures reliable operation in challenging environments.

Insufficient or improper lubrication can result in increased noise and vibration levels in deep groove ball bearings. The lubricant acts as a cushioning medium, absorbing shocks and reducing the transmission of vibrations. Proper lubrication minimizes the generation of noise and vibrations, resulting in smoother and quieter operation of the bearing.

Proper lubrication ensures effective load distribution within the deep groove ball bearing. The lubricant film helps distribute the applied loads evenly across the rolling elements and raceways, minimizing stress concentrations and preventing premature fatigue or failure of the bearing. This promotes the bearing’s load-carrying capacity and enhances its overall performance and reliability.

Adequate lubrication helps preserve the overall integrity of deep groove ball bearings. It reduces the risk of surface damage, pitting, and scoring, which can lead to accelerated wear and premature failure. Proper lubrication also prevents the formation of rust and corrosion, preserving the structural integrity of the bearing components and ensuring their long-term functionality.

In summary, proper lubrication of deep groove ball bearings is essential for reducing friction and wear, dissipating heat, protecting against corrosion and contamination, minimizing noise and vibrations, facilitating effective load distribution, and preserving the overall integrity of the bearing. By ensuring proper lubrication, the performance and longevity of deep groove ball bearings can be significantly enhanced, resulting in reliable operation and extended service life.

How do deep groove ball bearings enhance the performance of automotive components like alternators?

Deep groove ball bearings play a crucial role in enhancing the performance of automotive components, including alternators. These bearings provide several benefits that contribute to the efficient and reliable operation of alternators. Here’s a detailed explanation of how deep groove ball bearings enhance the performance of automotive components like alternators:

- Reduced Friction:

- High Load Capacity:

- Enhanced Durability:

- Smooth Operation:

- Reduced Maintenance:

- Compact Design:

Deep groove ball bearings are designed to minimize friction between the rotating components of an alternator. The smooth and precise rolling action of the bearings reduces friction losses, allowing the alternator to operate more efficiently. This leads to improved energy conversion and reduced power consumption, resulting in enhanced overall performance.

Automotive alternators often experience varying loads during operation. Deep groove ball bearings are engineered to handle both radial and axial loads effectively. They have a high load capacity, enabling them to withstand the demanding conditions and loads encountered in alternators. This ensures the bearings can support the rotating components of the alternator without premature wear or failure.

Deep groove ball bearings are manufactured using high-quality materials and advanced manufacturing processes. This results in bearings that are highly durable and resistant to wear, even under demanding operating conditions. The robust construction and materials used in deep groove ball bearings contribute to their longevity and ability to withstand the rigors of automotive applications, including alternators.

Deep groove ball bearings provide smooth and precise rolling motion, which is essential for the optimal performance of alternators. The low friction and high rotational accuracy of these bearings ensure that the alternator operates smoothly and without excessive vibration or noise. This smooth operation enhances the efficiency and reliability of the alternator, leading to improved overall performance.

The use of deep groove ball bearings in automotive alternators helps reduce the maintenance requirements. These bearings are designed for long service life and require minimal maintenance when properly lubricated and installed. Their durability and resistance to wear mean that they can operate reliably for extended periods without the need for frequent inspections or replacements, reducing downtime and maintenance costs.

Deep groove ball bearings have a compact design, which is advantageous for automotive applications where space is often limited. The compact size of these bearings allows for more efficient packaging and integration within the alternator assembly. This compact design contributes to the overall efficiency and performance of the alternator while optimizing the use of available space.

Overall, deep groove ball bearings enhance the performance of automotive components like alternators by reducing friction, providing high load capacity, enhancing durability, ensuring smooth operation, reducing maintenance requirements, and offering a compact design. These benefits collectively result in improved energy efficiency, reliability, and longevity of the alternator, ultimately enhancing the performance of the automotive system as a whole.

editor by CX 2024-05-09