Product Description

DETA

ZheJiang Leicester Bearing Technology Co., Ltd. is a specialized manufacturer that produces various types of bearings, including cylindrical roller bearings (7 series, 97 series, 3007 series, 20097 series), British standard tapered roller bearings, deep groove ball bearings, spherical plain bearings, self-aligning roller bearings, rolling mill bearings, and a variety of non-standard bearings.

At our core, we believe in “Quality, Creating Value,” and we have gained the trust and support of customers both domestically and internationally by delivering high-quality products.

In 2002, we received certification from the China Import and Export Product Quality Verification Center and obtained ISO 9001, ISO 2000, and IATF 16949 quality management system certifications. Our successful collaborations with renowned domestic and international enterprises have made us reliable and stable suppliers. Moreover, we have provided bearing components to well-known bearing manufacturers worldwide.

PRODUCT OVERVIEW

| Eaaring No | Di d |

mension D |

(mm) B |

Mass(kg) | Bearing No | DI d |

mension D |

(mm) B |

Mass(kg) |

| 604 | 4 | 12 | 4.0 | 6212 | 60 | 110 | 22 | 0.780 | |

| 606 | 6 | 17 | 17.0 | 6213 | 65 | 120 | 23 | 0.990 | |

| 608 | 22 | 7.0 | 0.0080 | 8214 | 70 | 125 | 24 | 1.050 | |

| 623 | 3 | 10 | 4.0 | 0.571 | 6215 | 75 | 130 | 25 | 1.200 |

| 625 | 5 | 16 | 5.0 | 0.0050 | 6216 | 80 | 140 | 26 | 1.400 |

| 634 | 4 | 16 | 5.0 | 0.0050 | 6217 | 85 | 150 | 28 | 1.800 |

| 635 | 5 | 19 | 6.0 | 0.0080 | 6218 | 90 | 160 | 30 | 2.150 |

| 680 | 9 | 22 | 7.0 | 6219 | 95 | 170 | 32 | 2.600 | |

| 618/3 | 3 | 7 | 2.0 | 0.0003 | 6220 | 100 | 100 | 34 | 3.150 |

| 618/4 | 4 | 9 | 2.5 | 0.0006 | 6221 | 105 | 190 | 36 | 00 |

| 618/5 | 5 | 11 | 3.0 | 0.0120 | 6222 | 10 | 200 | 38 | 4.350 |

| 6000 | 10 | 26 | 8.0 | 0.0190 | 6300 | 10 | 35 | 11 | 0.053 |

| 6001 | 12 | 20 | 8.0 | 0.5710 | 6301 | 12 | 37 | 12 | 0.060 |

| 6002 | 15 | 32 | 9.0 | 0.0300 | 6302 | 15 | 42 | 13 | 0.082 |

| 6003 | 17 | 35 | 10.0 | 0.0390 | 6303 | 17 | 47 | 14 | 0.120 |

| 6004 | 20 | 42 | 120 | 0.0690 | 6304 | 20 | 52 | 15 | 0.140 |

| 6005 | 25 | 47 | 12.0 | 0.0800 | 6205 | 25 | 62 | 17 | 0.230 |

| 6006 | 30 | 55 | 13.0 | 0.1200 | 6306 | 30 | 72 | 19 | 0.3680 |

| 6007 | 35 | 62 | 14.0 | 0.1600 | 6207 | 35 | 80 | 21 | 0.460 |

| 6008 | 40 | 68 | 15.0 | 0.1900 | 6309 | 40 | 90 | 23 | 0.630 |

| 6009 | 45 | 75 | 16.0 | 0.2500 | 6309 | 45 | 100 | 25 | 0.830 |

| 6571 | 50 | 80 | 16.0 | 0.2600 | 6310 | 50 | 110 | 27 | 1.050 |

| 6011 | 55 | 90 | 18.0 | 0.3000 | 6311 | 55 | 120 | 29 | 1.350 |

| 6012 | 0 | 96 | 18.0 | 0.4200 | 6312 | 60 | 130 | 31 | 1.700 |

| 6013 | 65 | 100 | 18.0 | 0.4400 | 6313 | 65 | 140 | 33 | 2.100 |

| 6014 | 70 | 110 | 20.0 | 0.6000 | 6314 | 70 | 150 | 35 | 2.500 |

| 6015 | 75 | 115 | 20.0 | 0.6400 | 6315 | 75 | 160 | 37 | 3.000 |

| 6016 | 80 | 120 | 22.0 | 0.8500 | 6316 | 80 | 170 | 39 | 3.600 |

| 6017 | 85 | 130 | 22.0 | 0.8900 | 6217 | 85 | 180 | 41 | 4.260 |

| 6018 | 90 | 140 | 24.0 | 1.1500 | 6318 | 90 | 190 | 43 | 4.900 |

| 6019 | 95 | 145 | 24.0 | 1.2000 | 6319 | 95 | 200 | 45 | 5.650 |

| 6571 | 100 | 150 | 24.0 | 1.2500 | 6320 | 100 | 215 | 47 | 7.000 |

| 6571 | 105 | 160 | 26.0 | 16,000 | 6401 | 12 | 42 | 13 | 0.048 |

| 6571 | 110 | 170 | 28.0 | 1.9500 | 6402 | 15 | 52 | 15 | 0.137 |

| 6200 | 10 | 30 | 9.0 | 0.0320 | 6403 | 17 | 62 | 17 | 0.271 |

| 850 | 12 | 32 | 10.0 | 0.571 | 6404 | 20 | 72 | 19 | 0.408 |

| 6202 | 15 | 35 | 11.0 | 0.0450 | 6405 | 25 | 80 | 21 | 0.528 |

| 6203 | 17 | 40 | 12.0 | 0.0650 | 6406 | 30 | 90 | 23 | 0.720 |

| 6204 | 20 | 47 | 14.0 | 0.1100 | 6407 | 35 | 100 | 25 | 0.936 |

| 6205 | 25 | 52 | 15.0 | 0.1300 | 6408 | 40 | 110 | 27 | 1.200 |

| 6206 | 30 | 62 | 16.0 | 0.2000 | 6409 | 45 | 120 | 28 | 1.550 |

| 6207 | 35 | 72 | 17.0 | 0.2900 | 6410 | 50 | 130 | 31 | 1.910 |

| 6208 | 40 | 80 | 18.0 | 0.3700 | 6411 | 55 | 140 | 33 | 2.320 |

| 6209 | 45 | 85 | 19.0 | 0.4100 | 6412 | 60 | 150 | 35 | 2.790 |

| 6210 | 0 | 90 | 20.0 | 0.4600 | 6413 | 65 | 160 | 37 | 3.360 |

| 6211 | 55 | 100 | 21.0 | 0.6100 | 6414 | 70 | 180 | 42 | 5.000 |

| “Aval lable typas:apan,Z.ZZ,RS;2RS,N,ZN | |||||||||

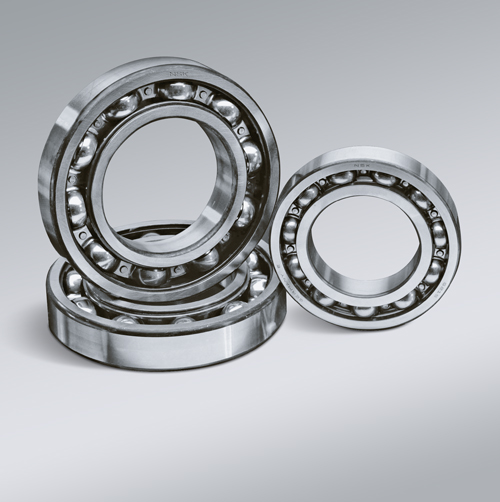

Deep groove ball bearings are the most representative of rolling bearings, with simple structure, They are easy to use and versatile .

Such bearings are non-separabal bearings,the inner and outer rings are rolled into a ditch arc type. They can bear radial load and axial load,with low coefficient of friction,high limiting speed .They are suitable for high-spped,low noise ,low vibration cccasions.

Deep groove balll bearings are widely used in auto-mobiles,machinetools,motors,instrumentation,construction machinery,railway vehicles,agricultural machinery and various equipment in machinery industry.

Detailed Photos

OUR PRODUCTS

SCOPE OF APPLICATION

PRODUCTION PROCESS

PRODUCT PACKAGING

1.industrial packing+industrial cartons+pallets

2.single brand box+brand cartons+pallets

3.follow customer’s requests

A.Plastic Tubes or Single Boxes ( Usually 10pcs in 1 plastic tube for steel bearings);

B.Cartons ( No more than 30kg for 1 carton );

C. Pallet ( Usually more than 400kg totally will use pallet )

D. Delivery time :7-35 days ( by sea or by air )

Generally,We will choose the most suitable packing method for products. If you have any special requirements for packing, please contact us in advance.

Company Profile

“Reliable quality, competitive prices, and excellent service” have always been our guiding principles. We have implemented a stringent quality control system, starting from raw material procurement to product manufacturing. Our company boasts a strong technical team, well-equipped testing facilities, and a robust ability to develop new products. With a commitment to delivering high-quality products and maintaining a good reputation, we aim to earn the trust of more customers.

ZheJiang Leicester Bearing Technology Co., Ltd. warmly welcomes both new and existing customers for discussions, guidance, and collaboration. We are eager to establish direct sales partnerships with businesses in various industries, both within the country and internationally.

As we embrace our dreams and uphold our values, honesty remains the foundation of our company. ZheJiang Leicester Bearing Technology Co., Ltd. looks forward to creating a bright future together with you!

OUR STRENGTHS

Q1: Can I get some samples?

A: Yes, sample order is available for quality check and market test. But you have to pay the sample cost and express cost.

Q2: Do you receive customized order?

A: Yes, ODM & OEM are welcomed.

Q3: What’s the lead time?

A: According to the order quantity, small order usually need 3-5 days, big order need negotiation.

Q4: What’s your payment terms?

A: We receive Escrow, T/T, West Union, Cash and etc.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Model No.: | Main Product Deep Groove Ball Bearing |

|---|---|

| Deliver Time: | 0-15days |

| Transport: | by Land or Sea or Air |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the signs of wear or damage in deep groove ball bearings, and when should they be replaced?

Deep groove ball bearings, like any mechanical component, can experience wear or damage over time. It is important to identify the signs of wear or damage in bearings and know when they should be replaced to prevent further issues. Here’s a detailed explanation of the signs of wear or damage in deep groove ball bearings and when they should be replaced:

- Abnormal Noise:

- Excessive Vibration:

- Increased Temperature:

- Irregular or Uneven Operation:

- Visible Wear or Damage:

- Lubrication Issues:

- Operating Conditions:

Unusual noises, such as grinding, clicking, or rumbling sounds, can indicate bearing wear or damage. These noises may occur during operation and can be an indication of insufficient lubrication, misalignment, or the presence of foreign particles. If abnormal noise is detected, it is recommended to inspect the bearings promptly and replace them if necessary.

Excessive vibration during operation can be a sign of bearing wear or damage. Vibrations may occur due to misalignment, imbalance, or the presence of faulty bearings. If the vibration levels are unusually high and cannot be attributed to other factors, the bearings should be inspected and replaced if needed.

Significantly increased operating temperature of the bearings can indicate wear or damage. Excessive friction caused by worn-out or misaligned bearings can generate excessive heat. If the temperature of the bearings exceeds the recommended operating limits, it is advisable to investigate the cause and replace the bearings as necessary.

Irregular or uneven operation of the equipment or machinery can be a symptom of bearing wear or damage. This may manifest as erratic or jerky movements, decreased performance, or decreased efficiency. If such irregularities are observed, the bearings should be inspected to determine if replacement is required.

Physical inspection of the bearings can reveal visible signs of wear or damage. These signs may include pitting, rust formation, scoring, or discoloration on the bearing surfaces. Excessive wear or damage that affects the smooth rolling motion or integrity of the bearings should prompt immediate replacement.

Problems with lubrication, such as inadequate or contaminated lubricant, can contribute to bearing wear or damage. Insufficient lubrication can lead to increased friction, heat generation, and accelerated wear. If lubrication-related issues persist despite proper maintenance, it may be necessary to replace the bearings.

The operating conditions of the equipment or machinery can also influence the lifespan of deep groove ball bearings. Factors such as heavy loads, high speeds, extreme temperatures, exposure to corrosive environments, or prolonged use can accelerate wear or damage. In such demanding conditions, bearings may need to be replaced more frequently to ensure reliable operation.

It is important to note that the timing of bearing replacement depends on various factors, including the severity of wear or damage, the criticality of the application, and the manufacturer’s recommendations. Regular inspection and maintenance practices, as well as monitoring of the aforementioned signs, can help determine the appropriate timing for bearing replacement. Consulting with bearing manufacturers or maintenance professionals can provide valuable guidance in assessing the condition of deep groove ball bearings and making informed decisions regarding replacement.

In summary, signs of wear or damage in deep groove ball bearings include abnormal noise, excessive vibration, increased temperature, irregular or uneven operation, visible wear or damage, lubrication issues, and demanding operating conditions. Prompt replacement of bearings exhibiting these signs is essential to prevent further damage, avoid equipment failure, and ensure the continued smooth and reliable operation of machinery or equipment.

Can you explain the design principles of deep groove ball bearings and their functions?

Deep groove ball bearings are designed based on specific principles to ensure their optimal performance and functionality. Here’s a detailed explanation of the design principles of deep groove ball bearings and their functions:

- Internal Geometry:

- Rolling Elements:

- Cage:

- Sealing and Shielding:

- Lubrication:

- Mounting and Fitting:

The internal geometry of deep groove ball bearings is characterized by the presence of deep raceway grooves in both the inner and outer rings. These grooves enable the bearings to accommodate radial loads, axial loads, or a combination of both. The geometry of the raceway grooves is designed to distribute the load evenly along the rolling elements, minimizing stress concentrations and maximizing load-carrying capacity.

Deep groove ball bearings utilize steel balls as rolling elements. The balls are typically made of high-quality bearing steel and are precision-ground to ensure smooth and consistent rolling. The number, size, and arrangement of the balls in the bearing determine its load-carrying capacity and rotational characteristics. The rolling elements reduce friction and enable the efficient transfer of loads, allowing the bearing to operate with minimal energy losses.

A cage, also known as a retainer, is used in deep groove ball bearings to separate and guide the rolling elements. The cage holds the balls in position, ensuring proper spacing and alignment, and preventing contact between them. The main function of the cage is to maintain ball separation, reduce friction, and enable smooth rotation. Common cage materials include steel, brass, or synthetic polymers.

Deep groove ball bearings may incorporate sealing or shielding mechanisms to protect the internal components from contaminants and retain lubrication. Seals are designed to provide a barrier against dust, dirt, and moisture, while shields offer protection from larger particles. These protective features help extend the bearing’s service life, improve reliability, and maintain proper lubrication conditions.

Lubrication is essential for the smooth operation and longevity of deep groove ball bearings. Proper lubrication reduces friction, heat generation, and wear of the bearing components. The choice of lubricant and the method of lubrication depend on the application requirements and operating conditions. Common lubrication methods include grease packing, oil bath, oil mist, or centralized lubrication systems. Adequate lubrication ensures optimal performance, reduces maintenance needs, and extends the bearing’s lifespan.

Deep groove ball bearings are designed for easy mounting and fitting onto shafts or in housings. They typically have standardized dimensions and tolerances to facilitate interchangeability. Proper mounting techniques, such as using the correct fitting tools and applying appropriate axial and radial clearance, are crucial for achieving optimal bearing performance, reducing stress, and preventing premature failure.

In summary, the design principles of deep groove ball bearings encompass internal geometry with deep raceway grooves, rolling elements in the form of steel balls, cages for ball separation, sealing or shielding mechanisms for protection, lubrication systems for friction reduction, and easy mounting and fitting. These design elements work together to ensure the smooth operation, load-carrying capacity, durability, and reliability of deep groove ball bearings.

Can you explain the role of shields and seals in preventing contamination of deep groove ball bearings?

Shields and seals play a critical role in preventing contamination of deep groove ball bearings. These protective components act as barriers, preventing the ingress of contaminants such as dust, dirt, moisture, and other harmful substances into the bearing’s internal components. Here’s a detailed explanation of the role of shields and seals in preventing contamination of deep groove ball bearings:

- Shield:

- Seal:

- Preventing Contamination:

- Selection and Maintenance:

A shield is a metallic or non-metallic disc that is typically made of steel, synthetic rubber, or a combination of materials. It is designed to cover a portion of the bearing’s outer ring, leaving a small gap between the shield and the inner ring. The primary function of a shield is to provide a physical barrier that blocks the entry of contaminants into the bearing. Shields are effective in preventing larger particles, such as dirt and debris, from reaching the bearing’s internal components while allowing grease or lubricant to flow within the bearing.

A seal is a flexible component typically made of rubber or synthetic materials. It is designed to completely enclose the bearing and create a tight seal between the outer and inner rings. Seals create a physical barrier that effectively blocks contaminants from entering the bearing. Unlike shields, seals provide a higher level of protection against fine particles, moisture, and other contaminants by forming a more complete seal around the bearing. This helps to maintain the integrity of the lubricant and reduce the risk of premature wear or damage to the bearing’s internal components.

Contamination is a major cause of premature bearing failure. When contaminants such as dirt, dust, or moisture enter the bearing, they can interfere with the lubrication, cause abrasive wear, or induce corrosion. This can lead to increased friction, heat generation, and accelerated wear, ultimately compromising the bearing’s performance and lifespan. Shields and seals act as protective barriers that prevent these contaminants from reaching the critical internal components of the bearing, preserving the lubricant’s integrity and maintaining a clean operating environment for the rolling elements and raceways.

Proper selection and maintenance of shields and seals are essential for their effectiveness in preventing contamination. It is important to choose shields or seals that are suitable for the specific application and operating conditions. Factors such as the type and size of contaminants, temperature variations, and rotational speeds should be considered when selecting the appropriate shielding or sealing solution. Regular inspection and maintenance of shields and seals are also important to ensure they remain in good condition. Damaged or worn shields or seals should be promptly replaced to maintain the bearing’s protection against contamination.

In conclusion, shields and seals play a crucial role in preventing contamination of deep groove ball bearings. By acting as protective barriers, they safeguard the bearing’s internal components from the ingress of contaminants, preserving the lubrication, reducing wear, and extending the bearing’s service life. Proper selection, installation, and maintenance of shields and seals are essential to ensure their effectiveness in maintaining a clean and contaminant-free environment within the bearing.

editor by CX 2024-04-04